Industry 4.0

PHD Chamber of Commerce and Industry organised an Industry Interactive Webinar on “Atmanirbhar Bharat amid Industry 4.0

कौशलम् विजयते : अर्थात: 'कौशल' की ही जीत होती है

Kaushalam Vijayate : Meaning: 'Skills always Win '

History is full of examples where Man or Women with Right Skills have conquered both Professional and Personal Life scenarios. Right Skills when acquired timely, evolve a man innately. Gamma Skills is founded to serve the purpose of fostering the 'Right skills' in most effective ways.

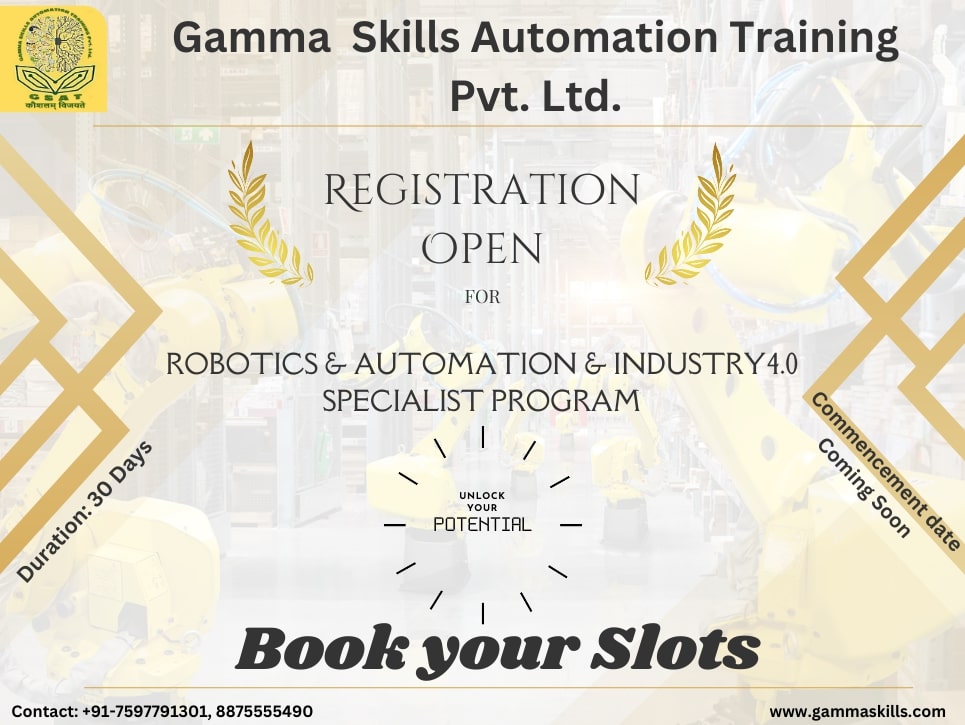

To develop hands-on skills of ‘Working engineering Professionals’ and Fresh Engineers, on Industry4.0 Technologies, through Competency based Training on world class Industrial Robots & Automation systems, with primary focus on enhancing scope of employability and fulfill manpower requirement of Automation Industry.

Our state-of-the-art lab encompasses advanced Industrial Training systems on technologies like PLC, Industrial Robot, Machine Vision system, Industrial 3-D Printing, IIOT, Machine Learning and Artificial Intelligence. With hands-on Training on these systems, we garner the advanced Automation Skillsof our Trainees andmake them ready to be an authentic Automation professional.

Technologies